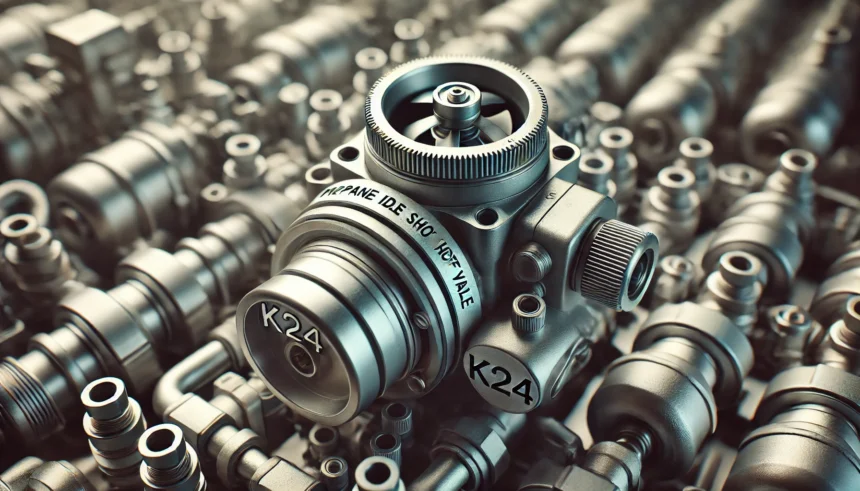

The K24 propane idle air shutoff valve is an essential part of propane-powered engines. It regulates airflow when the engine is idling, ensuring a proper air-to-fuel mixture.

This valve is crucial for maintaining smooth engine performance. Without it, the engine may experience rough idling or even stall unexpectedly.

Another key role of this valve is improving fuel efficiency. By controlling air intake precisely, it prevents excess fuel consumption, reducing operational costs.

Additionally, the valve enhances safety by shutting off air supply in case of malfunctions. This prevents uncontrolled engine behavior and potential damage.

Understanding the K24 propane idle air shutoff valve and its maintenance can help prolong engine life and improve overall performance.

The K24 Propane Idle Air Shutoff Valve: What is it?

The K24 propane idle air shutoff valve is a mechanical or electronic component that manages idle air intake in propane engines. It ensures the right air-to-fuel ratio for combustion.

This valve plays a critical role in preventing engine instability. If too much or too little air enters the system, the engine may struggle to run smoothly.

Unlike gasoline engines, propane engines rely on precise air regulation. This makes the K24 propane idle air shutoff valve even more essential for proper engine function.

When functioning properly, this valve contributes to a stable, controlled idle speed. This reduces engine wear and enhances operational reliability.

K24 Propane Idle Air Shutoff Valve: Essential for Engine Efficiency

The K24 propane idle air shutoff valve is a crucial component in propane-powered engines, ensuring proper airflow control when the engine is idling. It regulates the air intake to maintain an optimal air-to-fuel ratio, which is necessary for smooth engine operation, fuel efficiency, and reduced emissions.

Without this valve, engines may experience rough idling, stalling, or excessive fuel consumption. It also serves as a safety feature by shutting off airflow in case of malfunctions, preventing potential engine damage. Regular maintenance and timely inspections can help keep the K24 propane idle air shutoff valve functioning properly, ensuring long-term engine reliability.

Key Functions of the Valve

The K24 propane idle air shutoff valve helps regulate airflow into the engine while idling. This ensures efficient combustion and prevents fuel wastage.

One of its main benefits is improving engine performance. By controlling idle air intake, it prevents stalling, rough idling, and power fluctuations.

This valve also acts as a safety feature. In case of an engine malfunction, it can automatically shut off air supply, preventing potential hazards.

Additionally, it contributes to emission control. By optimizing air intake, the valve reduces unburned fuel emissions, making the engine more environmentally friendly.

Without this valve, propane engines would have difficulty maintaining a steady idle, leading to performance and safety issues.

Common Problems and Signs of Failure

A failing K24 propane idle air shutoff valve can cause rough idling. The engine may vibrate or feel unstable while running at low speeds.

Stalling is another common symptom. If the valve fails to regulate airflow correctly, the engine may shut off unexpectedly.

Excessively high idle speed may also indicate a problem. This happens when the valve allows too much air into the engine, causing uncontrolled revving.

Another warning sign is the check engine light. If this valve malfunctions, the engine control unit (ECU) may detect irregular airflow and trigger a warning.

If left unaddressed, these issues can lead to poor fuel efficiency and increased engine wear, making timely repairs essential.

Causes of Valve Malfunctions

Over time, the K24 propane idle air shutoff valve can wear out due to continuous operation. The internal components may degrade, affecting performance.

Dirt and contamination can also cause failures. Propane residue and air impurities may build up inside the valve, restricting airflow and causing erratic engine behavior.

Electrical issues are another potential problem. If the valve is electronically controlled, faulty wiring or damaged sensors can lead to malfunction.

Table: Common Causes of Valve Failure and Their Effects

| Cause | Effect on Valve | Engine Symptoms |

| Wear and Tear | Reduced function | Rough idle, stalling |

| Dirt & Contamination | Blocked airflow | High idle, poor efficiency |

| Electrical Issues | Unresponsive valve | Check engine light, unstable idle |

Regular inspections can help detect these issues early. Proper maintenance can extend the lifespan of the K24 propane idle air shutoff valve and keep the engine running smoothly.

Maintenance & Troubleshooting

Routine inspections of the K24 propane idle air shutoff valve can prevent unexpected failures. Checking for dirt buildup or visible damage helps in early problem detection.

Cleaning the valve is essential to maintain proper airflow. Removing propane residue and dirt can prevent clogging and ensure smooth operation.

If the valve is malfunctioning, testing the electrical connections is a good troubleshooting step. Damaged wiring or faulty sensors should be repaired promptly.

When replacement is necessary, choosing a high-quality valve ensures long-term reliability. Using compatible parts helps maintain engine efficiency.

Timely maintenance of this valve not only improves engine performance but also reduces repair costs in the long run.

Conclusion

The K24 propane idle air shutoff valve plays a crucial role in ensuring smooth engine operation. It regulates airflow to maintain a proper fuel-to-air ratio during idling.

A faulty valve can cause rough idling, stalling, or excessive fuel consumption. Recognizing early signs of failure can prevent costly engine repairs.

Regular maintenance, including cleaning and inspections, helps keep the valve in optimal condition. Major failures can be avoided by taking care of small problems early.

By understanding the function and importance of the K24 propane idle air shutoff valve, engine operators can improve efficiency, safety, and longevity.

FAQs

What is the function of the K24 propane idle air shutoff valve?

It controls airflow during engine idling to maintain the correct air-to-fuel ratio, ensuring smooth performance and fuel efficiency.

What are the signs of a failing K24 propane idle air shutoff valve?

Common symptoms include rough idling, stalling, high idle speed, and the check engine light turning on.

How does a faulty valve affect engine performance?

A malfunctioning valve can cause unstable idling, excessive fuel consumption, and potential engine shutdowns.

How can I maintain the K24 propane idle air shutoff valve?

Regular inspections, cleaning dirt buildup, and checking electrical connections help ensure proper function.

When should the K24 propane idle air shutoff valve be replaced?

Replace it if there are continuous airflow issues, persistent engine problems, or visible damage to the valve.